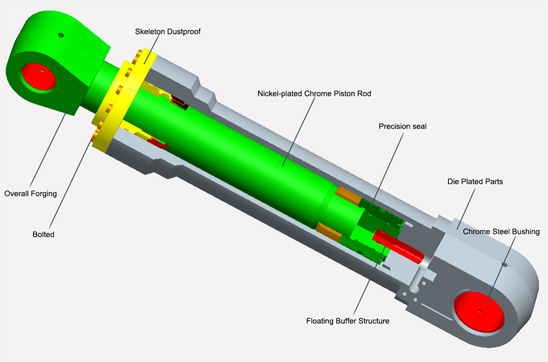

Hydraulic cylinders are integral components of hydraulic equipment, playing a crucial role in various applications across numerous industries. These devices convert hydraulic energy into mechanical force, enabling movement and lifting in machines that we encounter daily, such as excavators, trucks, forklifts, tractors, and aerial platforms. In essence, hydraulic cylinders are powerful actuators that utilize hydraulic fluid, typically hydraulic oil, to produce linear motion. A hydraulic system consists of several key components, with hydraulic cylinders being one of the four main elements alongside the hydraulic pump, valves, and the hydraulic reservoir. The hydraulic pump generates pressure by moving fluid through the system, which then travels to the hydraulic cylinder. Inside the cylinder, the pressurized fluid acts on a piston, creating force that can lift or push heavy loads with remarkable efficiency. One of the primary advantages of hydraulic cylinders in hydraulic equipment is their ability to deliver significant force relative to their size. This makes them particularly suitable for applications requiring high power output in a compact form. For instance, in construction and mining equipment, hydraulic cylinders enable heavy machinery to perform tasks such as digging, lifting, and moving large materials with ease. Hydraulic cylinders are available in various designs and configurations to suit specific applications. Common types include single-acting and double-acting cylinders. Single-acting cylinders use hydraulic pressure to move the piston in one direction, while a spring or gravity returns it to its original position. In contrast, double-acting cylinders allow fluid pressure to act on both sides of the piston, enabling movement in both directions and providing greater control over the actuator’s position.

The reliability and efficiency of hydraulic cylinders contribute significantly to the overall performance of hydraulic equipment. These cylinders are designed to withstand high pressures and are often constructed from durable materials such as steel or aluminum, ensuring longevity and minimal maintenance. Additionally, hydraulic cylinders can be equipped with various seals and components to prevent leaks and ensure optimal operation under varying conditions. In summary, hydraulic cylinders are vital components of hydraulic equipment that facilitate powerful linear motion in a wide range of applications. By converting hydraulic energy into mechanical force, they enable the effective operation of machinery used in construction, transportation, and many other sectors. Understanding the role and functionality of hydraulic cylinders enhances our appreciation of the technology that powers much of the heavy lifting and movement we rely on in our daily lives.

teknowfeed

teknowfeed