A hydraulic jack is a mechanical tool that uses hydraulic force to raise large objects. It works on the basis of fluid mechanics, namely the transfer of force from one place to another through a liquid. In the automotive, construction, and industrial sectors, hydraulic jacks are frequently utilized for jobs including moving heavy equipment, handling large things, and lifting cars for repair. Compared to mechanical jacks, they are preferred because they can lift large loads with comparatively minimal personal effort.

How Does a Hydraulic Jack Work?

Pascal's Law, which states that pressure applied to a confined fluid is transmitted

equally in all directions, provides the basis for the hydraulic jack's operation. The

fluid used in a hydraulic jack is usually oil, which is poured into a cylinder to

produce the required lifting power.

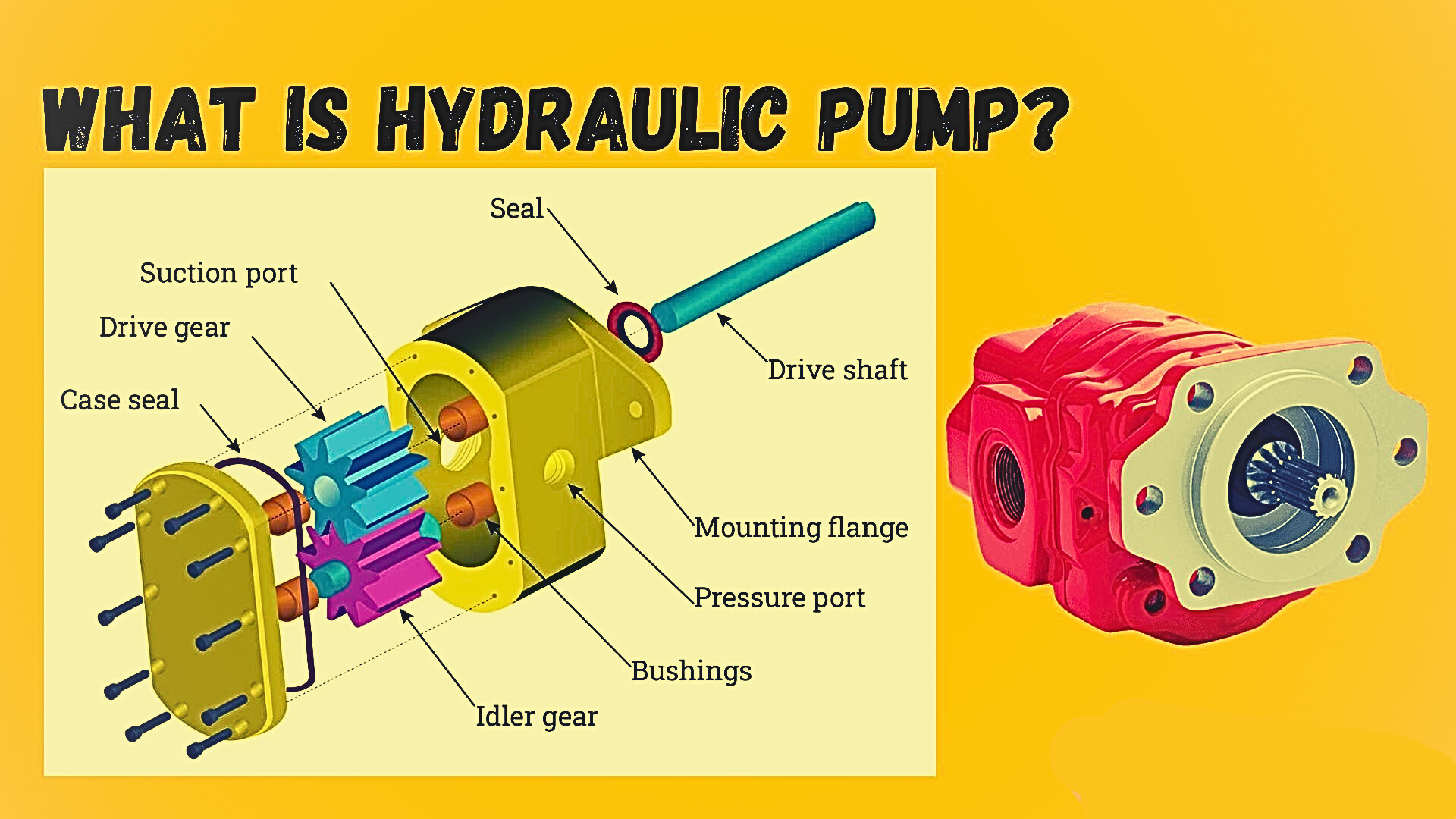

A pump, cylinder, piston, and hydraulic fluid reservoir make up the fundamental

components of a hydraulic jack. The hydraulic fluid is forced into the cylinder by the

pump when the operator turns it on, producing pressure. The load on top of the jack is

raised by the pressure that causes the piston within the cylinder to rise. Hydraulic

jacks are exceptionally successful in a variety of lifting applications because of their

design, which permits a minimal amount of manual labor to lift extremely big objects.

Types of Hydraulic Jacks

There are several types of hydraulic jacks, each designed for specific lifting needs:

- Bottle Jacks – These are compact and portable jacks, typically used in automotive applications. They are named for their bottle-like shape and can lift cars, trucks, and other vehicles with ease.

- Floor Jacks – Larger and more stable than bottle jacks, floor jacks are used in garages and workshops for lifting vehicles during tire changes or repairs. They typically feature a long handle for more precise control and greater lifting capacity.

- Toe Jacks – These jacks are ideal for lifting loads with minimal clearance. They can lift heavy machinery, equipment, or other objects in tight spaces by placing the toe of the jack under the load.

- High-Lift Jacks – As the name suggests, high-lift jacks are designed for lifting objects to higher elevations. They are often used in construction or off-road vehicles for heavy lifting tasks.

Advantages of Hydraulic Jacks

- Efficiency and Ease of Use – Hydraulic jacks can lift heavy loads with minimal physical effort, which makes them more efficient than mechanical jacks.

- Precision – Hydraulic jacks provide more precise control over lifting, making them ideal for delicate tasks where exact positioning is necessary.

- Versatility – These jacks can be used in a wide range of industries, from automotive repair to construction, making them highly versatile.

- Safety – Due to their design, hydraulic jacks are generally safer than manual or mechanical jacks. They are less likely to slip or fail under heavy loads, though it is essential to follow manufacturer guidelines and ensure the jack is rated for the load weight.

Conclusion

Hydraulic jacks are powerful, efficient tools that use hydraulic pressure to lift heavy loads with ease. With various types designed for specific tasks, they have become indispensable in industries such as automotive repair, construction, and manufacturing. Their ability to provide high lifting capacity with minimal manual effort makes them a go-to choice for both professionals and DIY enthusiasts.

teknowfeed

teknowfeed